Phenomenon of metamerism

Metamerism is an almost magic word implying that colours changing in a mysterious way. This is a quality problem for many industries. In practice it is a well-known physical phenomenon that can be controlled during the manufacturing process. This article describes the phenomena theoretically and give some practical advice on how to avoid problems.

What is metamerism?

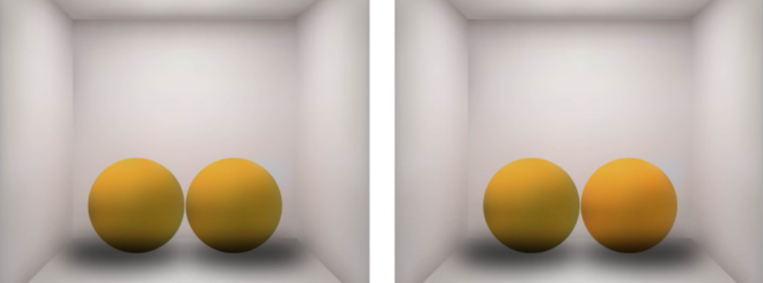

Metamerism is when two surfaces are perceived to have the same colour in one type of illumination, for example daylight, but are perceived to have different colours in another type of illumination, like fluorescent tubes.

This can influence products where different parts should have the same colour. If these parts are metameric a colour difference may be seen in different types of illumination, and the customer may perceive the difference as a sign on bad

quality.

The science behind the phenomenon

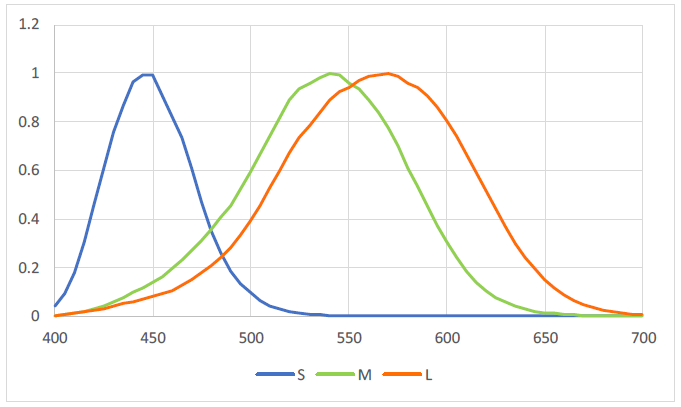

To understand metamerism we must understand the spectrum of different types of light and the sensitivity of the eye to these spectrums.

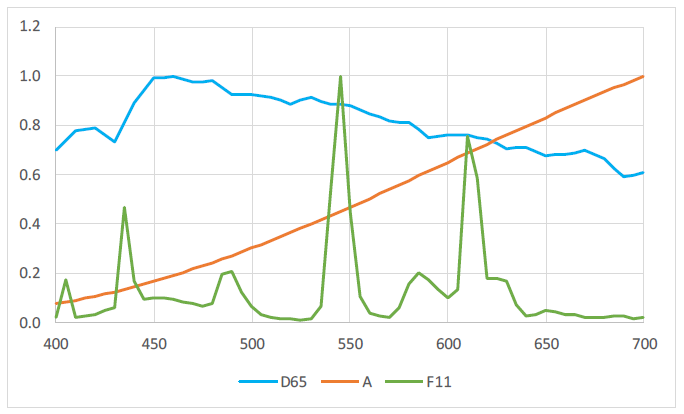

The spectrum of light is electromagnetic radiation with wavelengths from 400 up to 700 nm. Different types of light sources have spectrums with different spectral power distributions as shown in diagram 1.

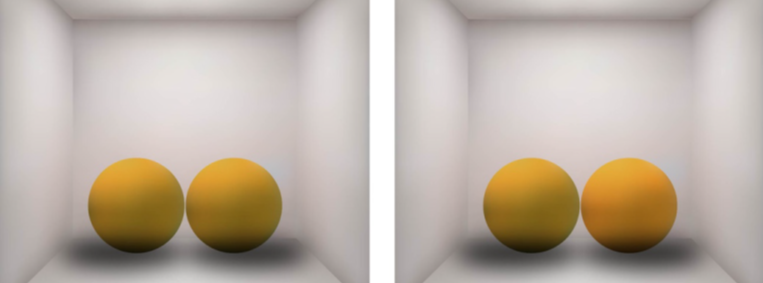

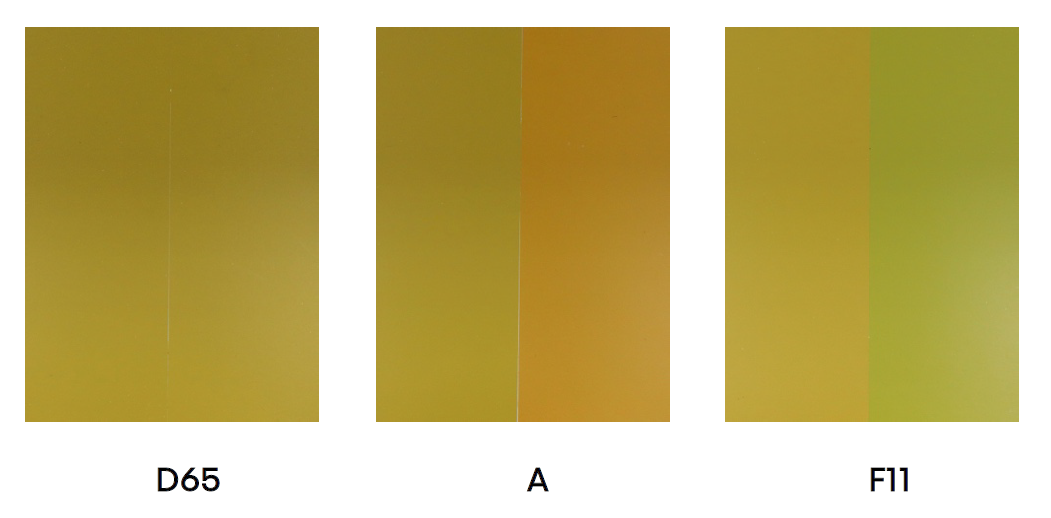

Figure 1. This is three photographs of the colour sample A and B mounted side by side. The first photograph is in daylight (D65), the second in incandescent light (A) and the third in fluorescent tube (F11). In D65 the two samples match, in A and F11 we see a colour difference due to metamerism.

What can be done?

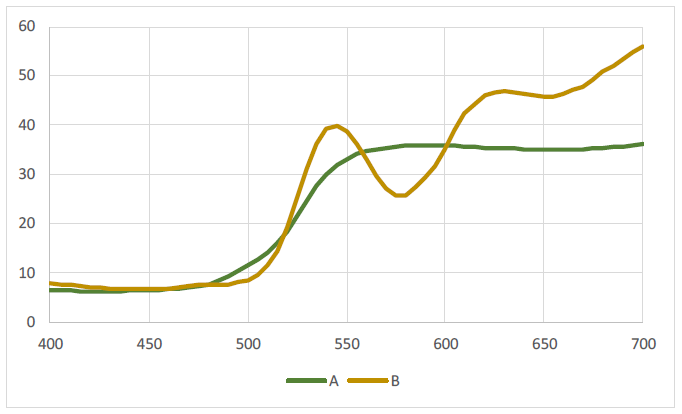

If two surfaces have the same spectral reflectance function, no metamerism will be seen between them. If we use the same material, colourants and mixing proportions for all parts of a product we will avoid metamerism.

However, by practical, economical and esthetical reasons, this is often not possible. If surfaces of different materials or different production batches is combined, measures must be taken to avoid metamerism.

For the product owner

• Use a colour standard that is correct for all types of light sources.

• Check products visually and/or instrumentally in different light sources against this colour standard. Use at least daylight and florescent light sources.

• Separate surfaces of different material that should have the same colour in a product by help of a divider. The divider should be a strongly contrasting colour. This will make it harder to discover metamerism.

For the producer

• If possible, use the same colourants as in the standard.

• Use as few colourants as possible.

• Avoid complementary mixing by using colourants with hue close to the colour standard.

• Aim for as flat spectral reflectance function as possible, this will create a colour where the hue changes less between different types of light sources, i.e. less risk for metamerism.