Colour quality in production with the NCS System

The NCS System is the only colour system on the market that is 100% based on our visual perception of colour. Our products are the highest quality on the market, and we take pride in our production process.

Professionals depend on accuracy. Engineers use accurate measurement technology, physicians use state-of-the-art medical equipment and musicians use the instrument with the clearest sound. The same is true for colour professionals. Colour is a decisive feature of whether a design or product will be successful or not, and to make the correct colour decisions we need to understand colour. It may be sufficient for a consumer to ask for a “light blue” shade or the colour “lavender”, but when working professionally with colour we need to be more precise. Therefore, we need a language for communicating colour and accurate reference tools to describe it.

Design tools for quality colour production

NCS Products

Coated paint on paper

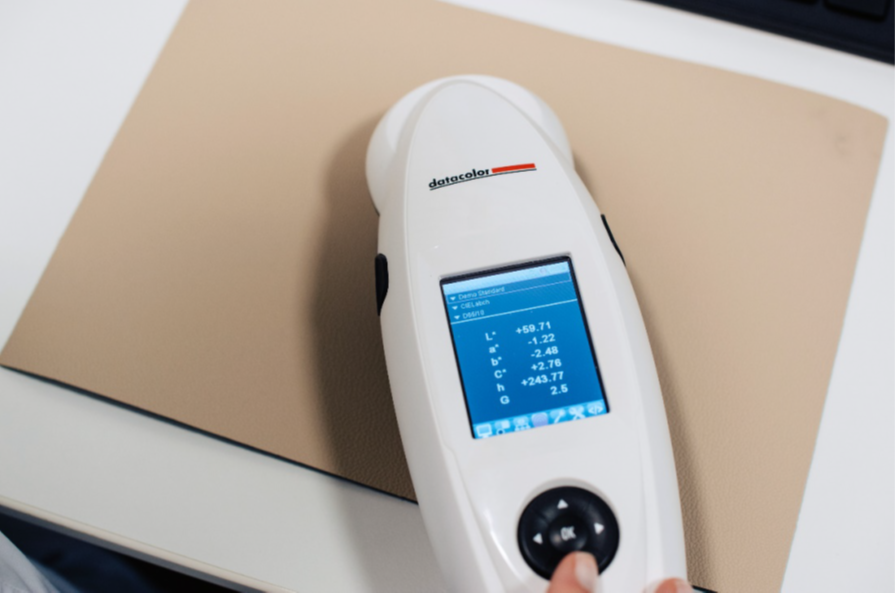

NCS Colour Products are produced using coated paint on paper. In contrast to printed samples and similar production methods, coated products can be produced with an accuracy where the variance between products is not perceivable (~0,4 ΔE00).

Why we use coated colour products

- Due to technical reasons, printed colour cards tend to have a greater variance between productions than coated colour cards do.

- Coated colour cards are solid, while printed colour cards uses small dots of ink. For example, a pink colour is printed as red dots on white paper, which is perceived as a solid pink, but is in fact a pattern.

- Coated colour cards can be adapted for different light sources, while printed colour cards cannot.

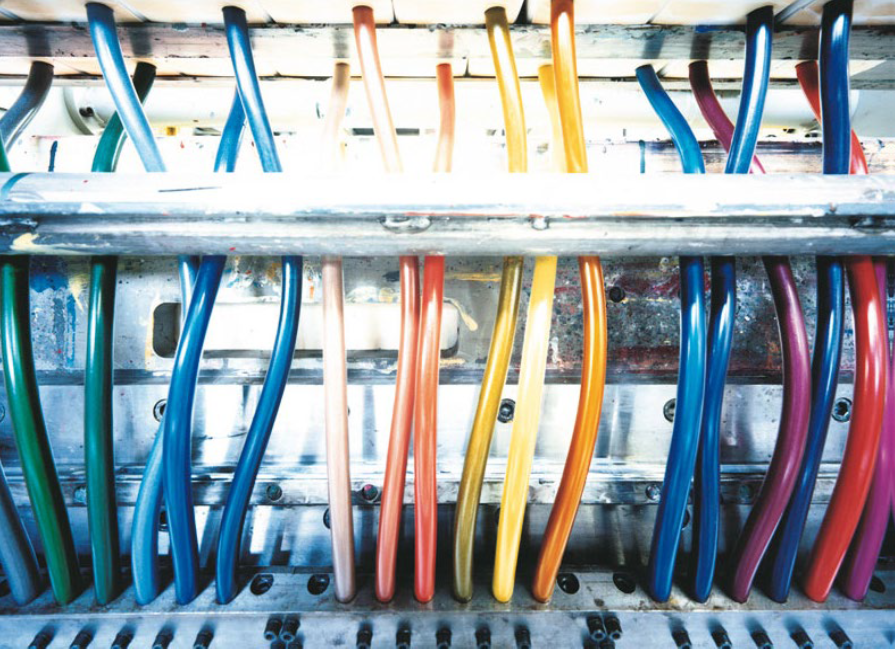

Other manufacturing industries

The same goes for coated colour in comparison to plastics or textiles. Coated colour products have the most solid properties and therefore are unparalleled as a master reference. However, in industrial productions a colour sample of the same material as the final product is generally used.

“Every produced batch of a colour card or master sample from NCS is traceable back to the original NCS Primary Standard. This is how we know that our colours are the same, not just from one product to the next but when you order the same colour in 50 years.”

– Karin Bünger, Head of Operations NCS Colour

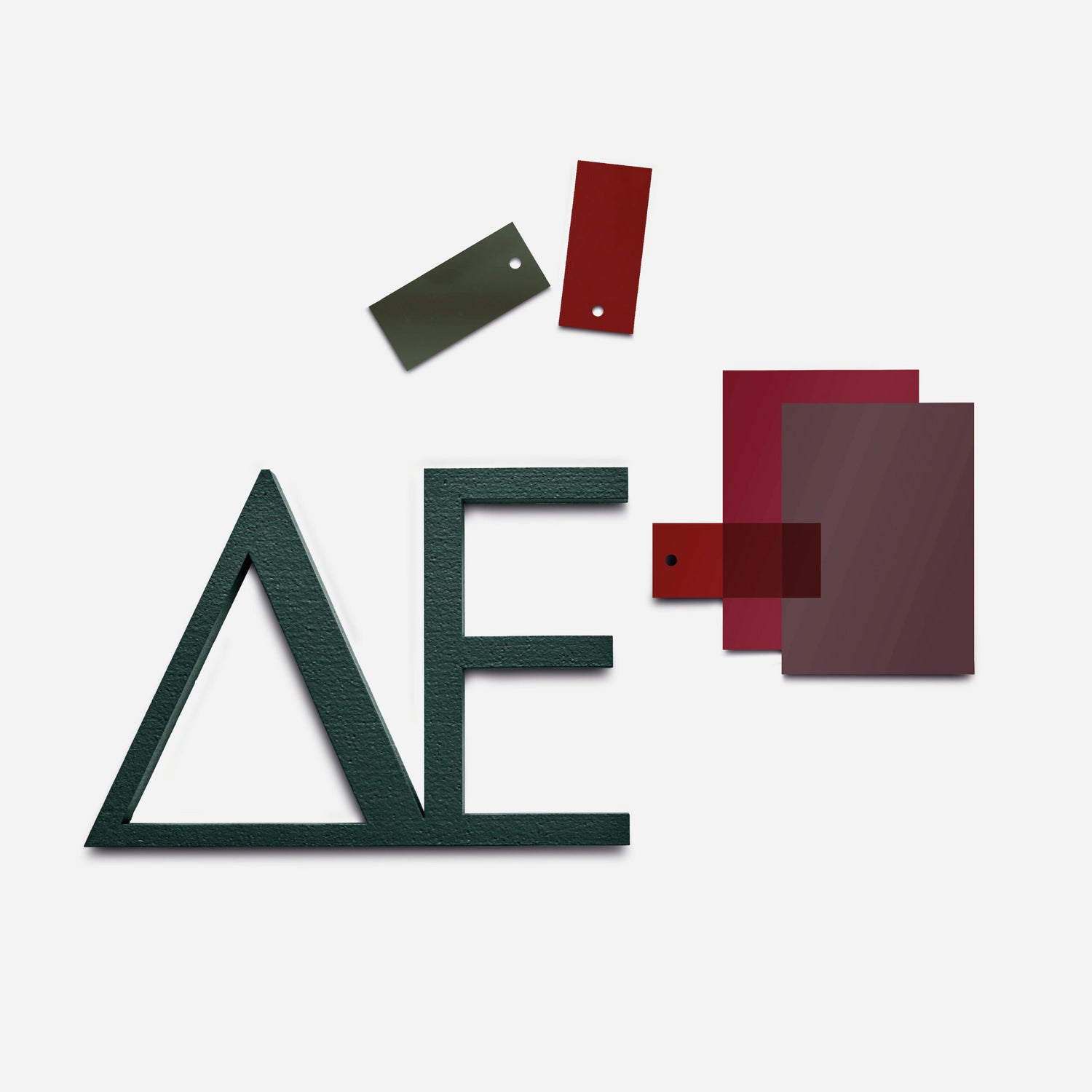

Colour quality control process

You can trust what you see

All productions of NCS Colour Products are rigorously checked, controlled and certified by the NCS Reference Lab to ensure that the final products have the perfect colour appearance. The target for the colour matching is a tolerance below 0.3 ΔE00 to ensure the best result. Since 2015, each production result has been documented in NCS Quality Report.

“We are proud to be able to say that we can offer you the best quality on the market that ensures your quality, colour communication and your customer trust and confidence.”

– Anders Nilsson, NCS Quality Centre Manager at NCS Colour

For more information regarding our products and services, please contact us at info@ncscolour.com.

Image credits:

Color Project European (CPE)